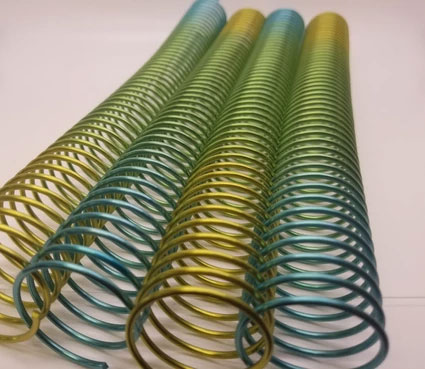

For years people have been trying to find a better solution for binding large documents using plastic rolls. If you want to buy a spiral coiled wire, you can look at this site.

Here are a few you might have tried:

Layout large 4:1 rolls by hand

• Oval jogging book

• Inserts with rollers having a “gap space” setting.

• 4:1 oval dies (oval dies can help)

• Insert with a mandrel drive system that allows you to split the book in half

• Operation with larger, more powerful reels

All of these are valiant attempts to solve the problem of tying large plastic rolls. But with documents as thick as 40 millimeters, installing the coils by hand is usually the only option that works.

Use plastic rolls in 3:1 increments.

The most common die-cut pattern for binding coils is the 4:1 step. If you are binding a standard font size document, you will need to drill 44 holes in the 11-inch binding edge.

That means 44 spiral stitches must be inserted into the document. Unfortunately, all of these holes create friction that limits and clogs the coil. This problem only gets worse as the book gets thicker because there is so much friction.

If you drill the same document with a 3:1 matrix, you are only drilling 33 holes at the 11" binding edge. Because you have fewer holes, you reduce friction. Also, because rolls are wider than others, 3:1 plastic rolls can make with a thicker thread, this makes the plastic spool harder and easier to install.